What is the reason why the metal circular saw machine is not sharp and how to solve it?

Release time:

2023-05-11 11:37

Source:

What is the reason why the metal circular saw machine is not sharp, and how to solve it?

The impact of the circular saw blade of the metal circular saw machine is not very large, such as cutting too large workpieces, the surface of the workpiece is not smooth, and the production efficiency is reduced. How to prevent the metal circular saw blade from being too blunt? Let's take a look at the factors and solutions for the sharpness of the metal circular saw machine blade!

Reasons why the circular saw blade of a metal circular saw machine is not sharp

There are many factors that affect the sharpness of the circular saw blade of a metal circular saw machine. The editor introduces the main factors that affect the sharpness of the circular saw blade.

1. The number or shape of teeth is wrong.

It is a very common problem that the number or shape of teeth is very common. When choosing a saw blade, the number of teeth or tooth profile is often ignored.

2. Magnetic powder clutch failure

The function of the magnetic powder clutch is to protect the saw blade, improve cutting efficiency, and ensure the stability of the cutting process. If there is a problem, it will seriously affect the work of the saw blade.

3. The feed speed is too fast

When the equipment is running, if the feed speed is too fast, it will seriously interfere with the normal operation of the saw blade, accelerate the wear of the saw teeth, and cause the saw blade to be not sharp.

4. Improper installation

Or when replacing the saw blade, the flange or screw is not installed correctly, and the saw blade produces a swinging hairpin when it is running, which accelerates consumption.

5. The cutting material is not clamped

The clamp of the metal circular saw machine is not adjusted properly, resulting in the material not being clamped, causing the saw blade to slip or increase the workload.

Solution to the blunt teeth of metal circular saw blades

1. When selecting saw blades, you need to strictly follow the relevant regulations to ensure the correct tooth shape or number of teeth, including regulations related to equipment and materials.

2. Regularly check the magnetic powder clutch in the metal circular saw blade to ensure normal operation. If any abnormality is found, it is necessary to stop the operation and have it checked by professionals.

3. The feed speed needs to be strictly controlled and must not be adjusted without authorization. If you want to speed up cutting or production, we need to ask professionals to adjust the whole.

4. When installing the metal saw blade, be sure to carefully check the parts to ensure their correctness.

5. Before starting the cutting work, be sure to carefully check the normal condition of the equipment and try to turn it for about 30 seconds.

In order to ensure the stability of metal circular saw blades and saw blades, necessary maintenance work needs to be carried out every day. If the circular saw blade is not sharp, replace the circular saw blade in time according to the situation!

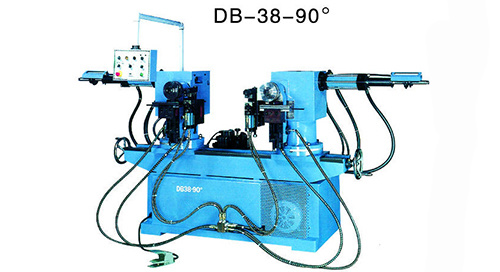

Zhangjiagang Hehe Machinery Co., Ltd. is a Taiwanese investment enterprise. Our main products are metal circular saw machines, tube shrinking machines, chamfering machines, tube cutting machines, tube bending machines, CNC tube bending machines, hydraulic tube bending machines, fully automatic tube cutting machines, fully automatic tube bending machines, etc. We are a company specializing in the research and development and manufacturing of metal circular saw machines, CNC tube bending machines, tube end forming machines and other tube machinery and equipment.

Previous article

Related News

What is the reason why the metal circular saw machine is not sharp and how to solve it?

The impact of the circular saw blade of the metal circular saw machine is not very large, such as cutting too large workpieces, the surface of the workpiece is not smooth, and the production efficiency is reduced. How to prevent the metal circular saw blade from being too blunt? Let's take a look at the factors and solutions for the sharpness of the metal circular saw machine blade!

High-speed metal circular saw machine saw blade maintenance precautions

Maintaining good working habits and formulating a strict maintenance system will help the smooth operation of the equipment. Metal circular saw machines, especially saw blades, must be carefully cleaned before or after work.

How to operate a metal circular saw

The metal circular saw machine is hydraulic, with vertical slides moving up and down, a firm feeding structure, accurate movements, and a floating material seat that does not damage the surface of the workpiece. Next, I will introduce the operation method of the metal circular saw machine.

Operating rules and characteristics of metal circular saw machines

The metal circular saw machine is hydraulic, with vertical guide rails for up and down advance and retreat, a firm feeding structure, accurate movement, and the floating seat does not damage the surface of the workpiece. The following is an introduction to the operation process and characteristics.

Practical Uses of Metal Circular Saw Machines

Metal circular saw machine is a form of circular saw. What are the practical uses? Here is a brief introduction to this question. Practical application of metal circular saw machine:

Advantages of using a metal circular saw machine

Metal circular saw machine is an industry that has emerged in recent years and belongs to metal cutting machinery and equipment. Many companies choose band saws or traditional old-fashioned equipment when processing metal materials, so companies must choose and replace new equipment now.